If you are looking for high-quality products, please feel free to contact us and send an inquiry, email: brad@ihpa.net

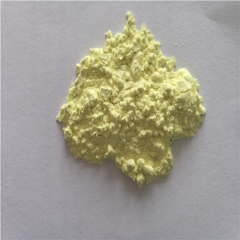

Among the various materials available for abrasives, aluminium oxide is a popular choice. It is a chemically inert, white material that has some unique properties. It is also widely used in ceramic industries. The most important properties of aluminum oxide are low heat retention, strength, and resistance to weathering. It also works well on metals and wood.

Aluminum oxide is available in various grades. It is available in a basic (pH 9.5) formulation or an acidic (pH 4.5) formulation. It is also available in a neutral formulation. It is a cost effective and reliable material for different applications. Besides, it has a low specific heat. It can be recycled several times.

White aluminum oxide is usually used on wood, and it works well on softer woods. It is also known for its hardness and perfect finish. It is available in a wide variety of grains, making it suitable for various applications. White aluminum oxide is also known for its excellent electrical insulating properties.

Brown aluminum oxide is another type of aluminum oxide, which is produced through fusing bauxite in an arc furnace. It is a very hard mineral, and it has a longer life than white aluminum oxide. It can be used to polish metal pieces, and it can be used to remove paint from surfaces. It is also used in refractories. It is a cheaper alternative to white and black aluminum oxide.

White Fused Aluminum Oxide is a high purity, fused aluminum oxide. It is available in microdermabrasion grade, as well as standard grade. It has superior electrical insulating properties and is known for its high refractoriness. It is also an excellent choice for delicate cleaning and blasting.

Inquiry us