If you are looking for high-quality products, please feel free to contact us and send an inquiry, email: brad@ihpa.net

Aluminium oxide is used as a catalyst support in many industrial processes such as hydrodesulfurization and some Ziegler-Natta polymerizations. However, aluminium oxidation is also an important contaminant in the production of alumina. Hence, it is essential to develop methods for limiting the oxidation reaction during processing and in the final product.

The oxidation reaction of aluminium is a spontaneous process that can lead to the formation of the low-melting, brittle aluminium oxide, corundum. The reaction is driven by the strong electrostatic interaction between aluminium ions and oxygen molecules. This strong interaction can also be influenced by the presence of other ions such as chloride or sulphide.

For example, exposing aluminium to chlorine gas leads to the formation of the soluble compound aluminium chloride (AlCl2). The reaction with sulphur dioxide leads to the formation of the brittle aluminium sulfate anhydride, Al2SiO4. This is known as the galvanic corrosion reaction. The corrosion is slow, but it eventually eats through the aluminium oxide skin and exposes bare metal. This is called the corrosive attack.

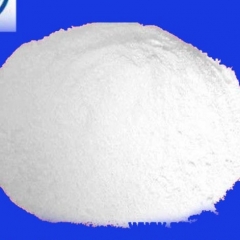

Alumina is a white, brittle material that has good heat and electrical conductivity. It is made by leaching the ore bauxite with caustic soda, precipitating the resulting hydrated aluminium oxide, washing and filtering it to obtain the alumina hydrate, and finally calcining to remove water to produce anhydrous aluminium oxide. The alumina is the raw material for making many common products, such as pots and pans, foil, mirrors, and other household items.