If you are looking for high-quality products, please feel free to contact us and send an inquiry, email: brad@ihpa.net

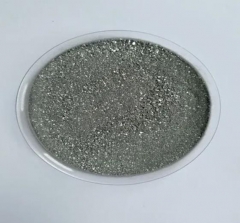

Aluminum oxide is a hard crystalline mineral with the chemical formula Al2O3. It is used for its electrical insulating properties and for its extreme resistance to abrasion. It is also used as a substrate for integrated circuits. Aluminium oxide is produced by leaching the ore bauxite with caustic soda and then precipitating the resultant alumina hydrate. It is then washed, filtered and calcined to yield the anhydrous aluminium oxide.

Inhalation exposure to 100 mg/hr aluminium, in powder form or 92 mg/hr, as a fume, each day for 9-13 months caused significant retention of aluminium in the lungs of rats and hamsters. However, inhalation of fresh air cleared the lungs rapidly and did not produce any further respiratory symptoms or evidence of lung damage.

Alumina ceramics are the hardest, strongest, and stiffest of all oxide ceramics. They have a high compressive strength, excellent insulation properties, and are resistant to acidic and sulfous atmospheres. They also have good dielectric strength and are inert to many chemicals.

Alumina is also very versatile as a blasting media. It can be used to deburr parts, impart an anchor pattern or to create a deep etch to aid in the adhesion of coatings and paints. It can be used to remove rust, mill scale, failing paint or any other contaminants from the surface of a part. It can also be used in a dry or wet blasting process to strip surfaces such as galvanized metals to clean them for re-use.