If you are looking for high-quality products, please feel free to contact us and send an inquiry, email: brad@ihpa.net

Aluminum is one of the most common metals used in manufacturing. It is a durable and lightweight material that can be made into many different types of components and accessories. It also has excellent corrosion and wear resistance.

Abrasive Media

Sand blasting is the process of cleaning and preparing an object by removing surface imperfections using abrasive materials. It is often used to prepare parts for paint and other coatings, but can be applied to many other items.

Choosing the Best Abrasive for Blasting Aluminium

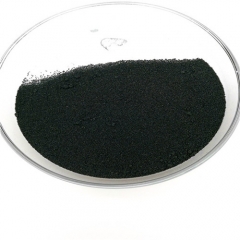

There are several types of abrasives available for sandblasting. Some of these include glass beads, Sodium Bicarbonate, and Aluminum oxide.

Depending on the type of product you’re blasting, the right abrasive will make a huge difference to the results. For example, if you’re blasting an aluminum wheel to remove factory paint and primer, a softer abrasive like glass beads will produce a smoother surface that is easier for the new coating to grip to.

Other abrasives for sandblasting are tungsten carbide, boron carbide, and silicon carbide. These abrasives are more resistant to damage than mineral abrasives, so they are sometimes used in smaller, less expensive blasting systems. However, they can be dangerous if inhaled. They can also break down quickly and leave dust, so it’s important to choose the abrasive that will be safe for you and your employees.