If you are looking for high-quality products, please feel free to contact us and send an inquiry, email: brad@ihpa.net

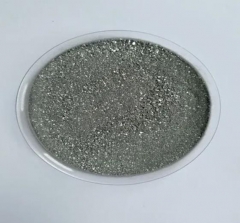

About alumina Aluminum Oxide Al2O3 nanopowder: The molecular formula of m-alumina is Al2O3. the molar mass of alumina is 101.96 g/mol. al2O3 is an electrical insulator. It has a fairly high thermal conductivity for ceramic materials. Rice alumina is available in activated, super-activated, acidic, basic and neutral grades and in flash grades, TLC, biomass purification, decolorization, dioxin analysis, PCB removal, pyrogen removal and biotechnological wide pore forms. Alumina is typically available immediately in most quantities. High purity, submicron and nanopowder forms can be considered. Alumina can also be made into granules, pellets, powders, sputtering targets, tablets and nano-powders. Typical and custom packaging and other research, technical and safety (MSDS) data are available. We are a trusted global alumina manufacturer and alumina supplier. If you want to buy alumina al2o3 powder in bulk, please feel free to ask for the latest alumina prices.

How is alumina Aluminum Oxide Al2O3 produced? Alumina is produced by the bauxite process. The Bayer process is divided into four steps. First, the bauxite is crushed, washed and dried, then dissolved at high temperature with caustic soda. Next, the mixture is filtered to remove impurities called "red mud" and properly discarded. The remaining alumina solution is transferred to a high tank called a precipitator. In the precipitator, the hot solution begins to cool and aluminum hydroxide seeds (very small particles) are added. The aluminum hydroxide seeds stimulate the precipitation of solid aluminum hydroxide crystals. The aluminum hydroxide precipitates at the bottom of the tank and is removed. Finally, all remaining caustic soda in the aluminum hydroxide is washed and heated to remove excess water. After this process, the alumina (aluminum oxide) appears as a fine white powder. It looks like sugar used in baking, but it is hard enough to scratch glass plates. Applications of alumina Aluminum Oxide Al2O3: Most of the alumina produced is used to make aluminum metal. Oxygen usually reacts with metallic aluminum to catalyze corrosion. However, when combined with oxygen to form alumina, it forms a protective coating and prevents further oxidation. This adds strength and makes the material less susceptible to deterioration. Aluminum oxide is used as an analytical reagent, dehydrating organic solvent, adsorbent, catalyst for organic reactions, abrasive, polishing agent, raw material for smelting aluminum, and refractory material. Medical industry Because of its hardness, biological inertness and chemical properties, alumina is used in hip replacement prostheses, bionic implants, artificial eye replacements, tissue-enhancing materials, and dental implants such as crowns, abutments and bridges. It is the material of choice for bearings. It is also used in laboratory equipment and tools such as crucibles, furnaces and other laboratory appliances. Military and protective equipment Aluminum oxide's strength and lightweight properties help reinforce body armor, such as breastplates and armor for automobiles and aircraft, which is its largest market. Aluminum oxide is also used to synthesize sapphire bulletproof windows and ballistic protection systems. Electrical and electronics industry Its high melting and boiling points, as well as its excellent heat resistance, make alumina an ideal material for high-temperature furnace insulators and electrical insulators. Alumina films are also an important part of the microchip industry. Its other uses include spark plug insulators, microelectronic substrates and insulating heat sinks. Brown alumina oxide is an excellent blasting media because brown alumina oxide is one of the hardest abrasives.