If you are looking for high-quality products, please feel free to contact us and send an inquiry, email: brad@ihpa.net

Aluminum oxide is the most commonly manufactured abrasive. This mineral is used in abrasive blasting and lapping operations. Its purity determines the color and strength of the abrasive. There are several different types of aluminum oxide wheels available in the market. Choosing the right wheel for your application ensures consistent performance.

General-purpose aluminum oxide wheels are usually gray in color. They are best for grinding steels and alloy steels. These wheels are typically 95 percent pure. However, abrasives vary in their strength, toughness, and grit size. The grit of the wheel should be selected to match the type of material being ground.

If you're working with a soft metal, choose a wheel with a coarse grain. You can also use a resinoid wheel for fine finishes.

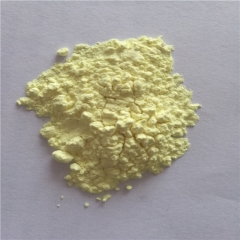

For grinding non-ferrous metals, you can use silicon carbide wheels. Silicon carbide is a very hard grain that's considered super-abrasive. Unlike other grains, it's also quite friable. Using a silicon carbide wheel provides an excellent grind on both soft and hard alloys.

In addition to abrasive wheels, you can also find contact wheels. Cloth contact wheels are also available. Manufacturers of contact wheels can offer you cloth or felt contact wheels with a durometer of 90 or more.

Abrasive wheels are used for a wide variety of applications. They can be used for abrasive blasting, removing paint, and cleaning metal surfaces.

Aluminum oxide wheels are typically used in the stainless steel industry. However, you can also find wheels used for gears, instrument frames, and other metals. When using an aluminum oxide wheel, make sure to mount it properly on a grinder. Also, be careful not to overwork it. Besides, do not store the grinding wheel in wet conditions.

Inquiry us