If you are looking for high-quality products, please feel free to contact us and send an inquiry, email: brad@ihpa.net

When people think about aluminium oxide finishing, they usually envision a hard finish that protects hardwood floors from scratches and other forms of damage. However, these finishes also do a lot more than that. For example, they can also help protect the wood from fading by blocking the sun’s UV rays.

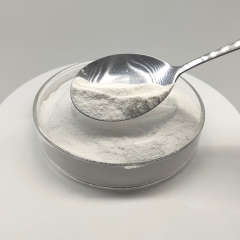

When you break down the name of this kind of anodizing, it comes from the fact that aluminum and oxygen are combined to create it. The resulting compound is alumina, which can be found in everything from ruby and sapphire gemstones to aluminum metal. It’s a versatile material that is commonly used in abrasive sandpaper and even as an abrasive for grinding and polishing applications.

These abrasives are created with different mesh sizes, such as 70, 120, and 220. The smaller mesh sizes are finer and more gentle, while the larger ones are more aggressive and create a rough surface for the paint or coating to adhere to.

One of the benefits of this particular type of anodizing is that it’s non-toxic. This is because the aluminum oxide particles are added to a water-based urethane and infuse themselves with it during the manufacturing process. The finish is applied to wood flooring in the factory, and as such, there’s no need to worry about off-gassing. This can be a concern with many stains and other kinds of finishes that are applied on-site, since the chemicals in them often enter the air as they dry.